Space launch systems

Space launch systems

Space launch systems

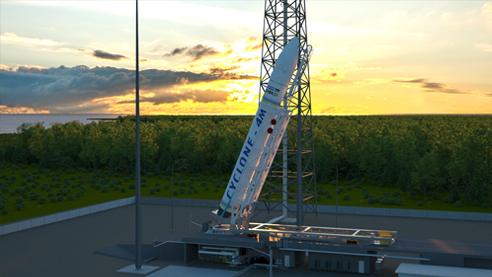

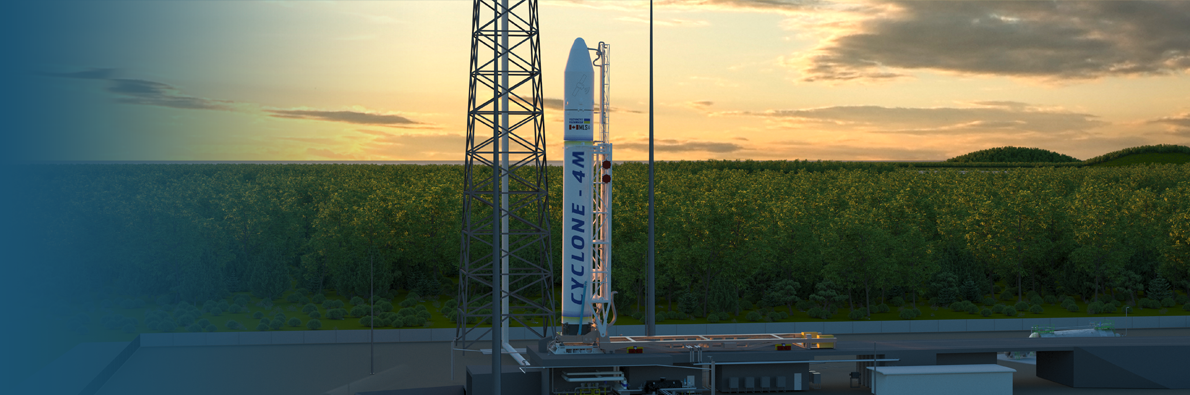

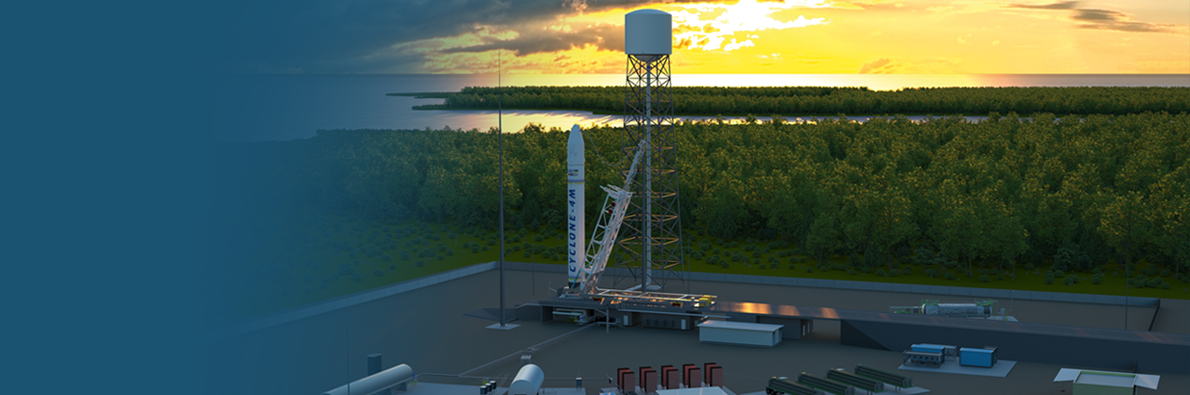

SLS BASING MODES

SLS STATIONARY BASING

SLS Stationary Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Launch mission duration (depending on ILV class), max, days | 25 |

| Duration of ILV prelaunch and launch operations on launch site, max, days | 3 |

| The following conditions are ensured in SC processing facility: | |

| air temperature, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness in facility, class | 8 ISO |

| Resistance of equipment to external effects during operations in launch area: | |

| ambient air temperature, °С | from minus 50 to plus 50 |

| maximal wind speed during ILV launch at 10 m altitude above ground surface, m/s | 15 (with gusts up to 21) |

*The data presented are for reference and may vary depending on ILV types.

SLS Sea Basing

SLS Sea Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Duration of launch mission without taking into account sea transit, max, days | 25 |

| Duration of prelaunch processing and launch operations at launch point, max, days | 3 |

| The following conditions are ensured in SC and PLU ATB facility: | |

| air temperature during assembling, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness in SC processing rooms, class: | 8 ISO |

| GSE resistance to external effects during operations in launch area: | |

| ambient air temperature, °С | plus 10 to plus 35 |

| relative air humidity, average annual value, % | 80 |

| wave height, m | up to 2,5 |

| maximal wind speed during ILV launch at 10 m altitude above sea surface, m/s | 10 |

*The data presented are for reference and may vary depending on ILV types.

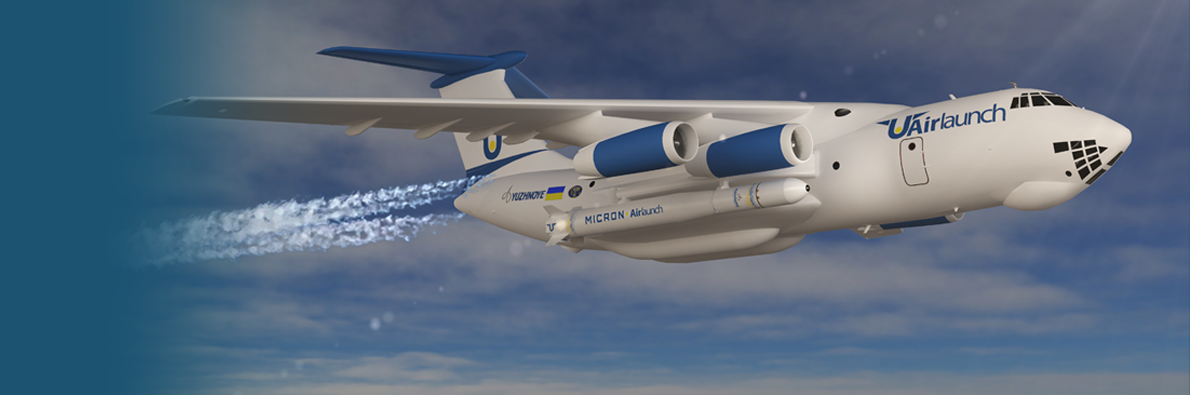

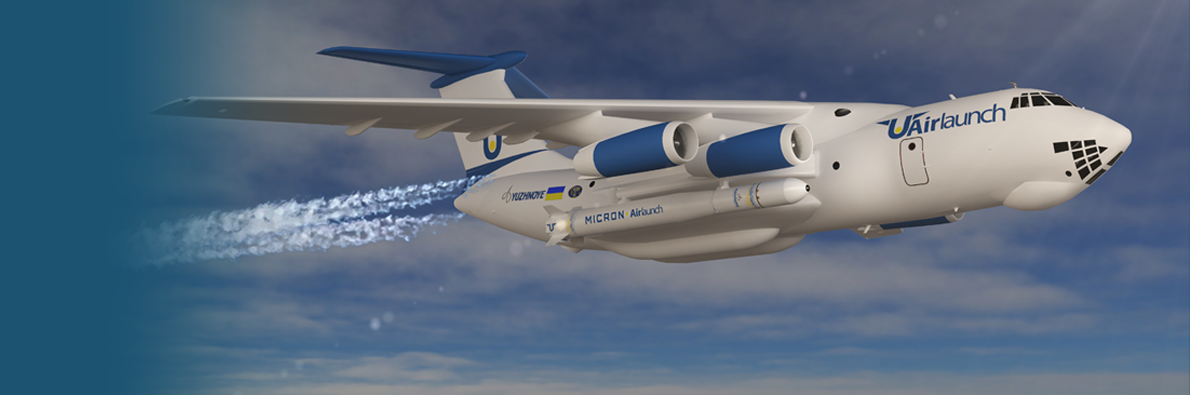

SLS Airborne Basing

SLS Airborne Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Duration of launch mission,max, days | 20 |

| Carrier aircraft flight time till ILV launch, max, hours | 5 |

| Air temperature in carrier aircraft cargo nacelle, °С | plus 5 to plus 25 |

| The following conditions are ensured in SC processing facility: | |

| air temperature, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness, class | 8 ISO |

*The data presented are for reference and may vary depending on ILV types.

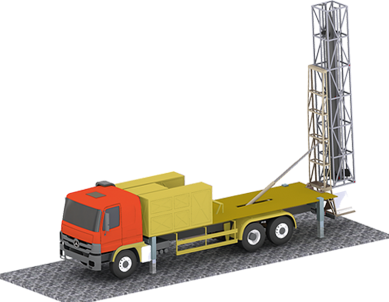

SLS Mobile Basing

SLS Mobile Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of meteorological rockets accommodated on mobile launcher | 1 |

| Wheel arrangement | 6 х 2, 6 х 4 |

| Engine power, kW | 250 – 400 |

| Fuel | Diesel fuel |

| Transport vehicle | Series-produced |

| Ecological standard, not worse | Euro 5 |

| Cruising range by control fuel consumption, km | 900 |

*The data presented are for reference and may vary depending on ILV types.

SLS BASING MODES

SLS STATIONARY BASING

SLS Stationary Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Launch mission duration (depending on ILV class), max, days | 25 |

| Duration of ILV prelaunch and launch operations on launch site, max, days | 3 |

| The following conditions are ensured in SC processing facility: | |

| air temperature, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness in facility, class | 8 ISO |

| Resistance of equipment to external effects during operations in launch area: | |

| ambient air temperature, °С | from minus 50 to plus 50 |

| maximal wind speed during ILV launch at 10 m altitude above ground surface, m/s | 15 (with gusts up to 21) |

*The data presented are for reference and may vary depending on ILV types.

SLS Sea Basing

SLS Sea Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Duration of launch mission without taking into account sea transit, max, days | 25 |

| Duration of prelaunch processing and launch operations at launch point, max, days | 3 |

| The following conditions are ensured in SC and PLU ATB facility: | |

| air temperature during assembling, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness in SC processing rooms, class: | 8 ISO |

| GSE resistance to external effects during operations in launch area: | |

| ambient air temperature, °С | plus 10 to plus 35 |

| relative air humidity, average annual value, % | 80 |

| wave height, m | up to 2,5 |

| maximal wind speed during ILV launch at 10 m altitude above sea surface, m/s | 10 |

*The data presented are for reference and may vary depending on ILV types.

SLS Airborne Basing

SLS Airborne Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of launches per year | 12 |

| Duration of launch mission,max, days | 20 |

| Carrier aircraft flight time till ILV launch, max, hours | 5 |

| Air temperature in carrier aircraft cargo nacelle, °С | plus 5 to plus 25 |

| The following conditions are ensured in SC processing facility: | |

| air temperature, °С | plus 18 to plus 25 |

| relative humidity, % | up to 80 |

| environment cleanliness, class | 8 ISO |

*The data presented are for reference and may vary depending on ILV types.

SLS Mobile Basing

SLS Mobile Basing

DESCRIPTION

BASIC SPECIFICATIONS*

| Number of meteorological rockets accommodated on mobile launcher | 1 |

| Wheel arrangement | 6 х 2, 6 х 4 |

| Engine power, kW | 250 – 400 |

| Fuel | Diesel fuel |

| Transport vehicle | Series-produced |

| Ecological standard, not worse | Euro 5 |

| Cruising range by control fuel consumption, km | 900 |

*The data presented are for reference and may vary depending on ILV types.