Services

Services

Project description

STRENGTH TESTS

Strength tests are performed to obtain data on the state of a test article when exposed to external and internal loads. Strength test articles include aerospace equipment, engineering products, power industry equipment, building structures, models, fragments of products, etc.

The test articles can be subjected to static and dynamic loading, with test parameters recorded and subsequently processed. Models of loading equivalent to actual operational loading are built, data are collected, recorded, and processed, and the tests are controlled from information-computer systems.

випробування

External load tests

A wide range of static strength and stability tests is run under concentrated and distributed loads, reproducing any combination of forces required.

The tests by a combination of loads are performed in manual and automated modes.

| Loading, tf | від 2 до 300 |

| Test article size, m | 30х10х18 |

| Deformation measurement range, % | 0,3…2 |

| Displacement measurement range, mm | 0…1500 |

| Measurement channels | 96 |

Mechanical characteristics of materials are measured under load of up to 200 tf.

The test articles are subjected to external pressure of up to 10 kgf/cm2 by vacuum degassing in dedicated degassing chambers.

External load tests

A wide range of static strength and stability tests is run under concentrated and distributed loads, reproducing any combination of forces required.

The tests by a combination of loads are performed in manual and automated modes.

| Loading, tf | від 2 до 300 |

| Test article size, m | 30х10х18 |

| Deformation measurement range, % | 0,3…2 |

| Displacement measurement range, mm | 0…1500 |

| Measurement channels | 96 |

Mechanical characteristics of materials are measured under load of up to 200 tf.

The test articles are subjected to external pressure of up to 10 kgf/cm2 by vacuum degassing in dedicated degassing chambers.

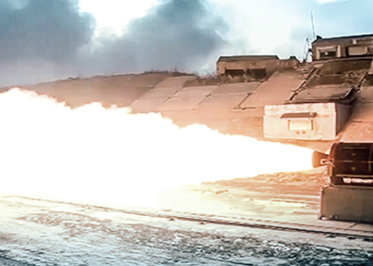

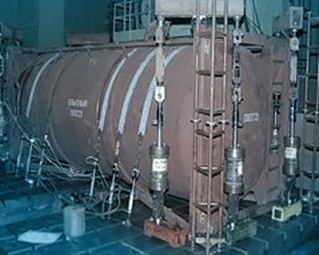

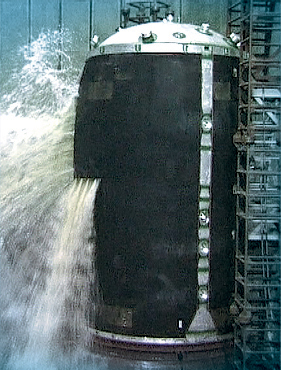

Internal pressure tests

Loading by internal pressure can be supported using water and hydraulic oil.

| Pressure with water as a working fluid, kgf/cm2 | 500 |

| Pressure with hydraulic oil as a working fluid, kgf/cm2 | 320 |

The test articles are subjected to cyclic loading by internal pressure of up to 200 tf.

Loading by internal pressure can be supported using water and hydraulic oil.

| Pressure with water as a working fluid, kgf/cm2 | 500 |

| Pressure with hydraulic oil as a working fluid, kgf/cm2 | 320 |

The test articles are subjected to cyclic loading by internal pressure of up to 200 tf.

The test articles are strength-tested with harmonic, random, and shock vibrations, followed by a frequency-response analysis.

The test wave forms include sinusoidal, triangular, single pulses, pulse trains, random oscillations, seismic spectrum, etc.

| Test article mass, kg | 0,1-2000 |

| Dynamic force, tf, not more than | 9 |

| Frequency, Hz | 5-3000 |

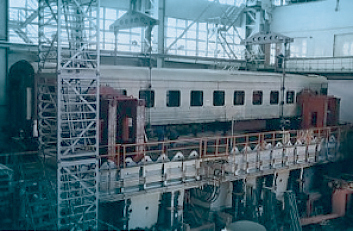

Bench and full-scale tests of structures and transportation systems under transportation and other types of dynamic loads are performed in operational and/or forced loading modes.

| Test article mass, tons, not more than | 160 |

| Dynamic force of a single force actuator, tf, not more than | |

| Force actuator rod displacement amplitude, mm, not more than | ±135 |

| Force actuator rod vibration acceleration, m/s2, not more than | 119 |

| Frequency, Hz | 1-100 |

| Mode | Continuous |

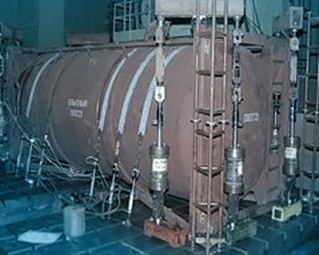

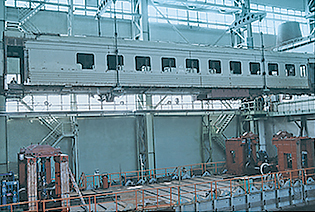

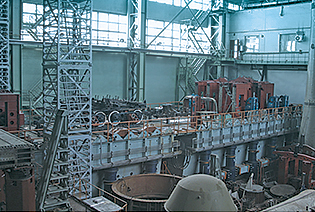

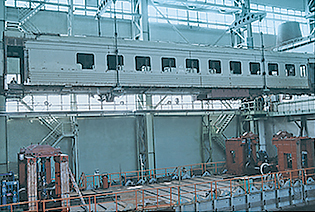

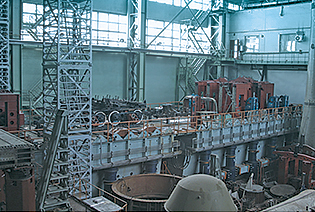

Preparation for tests of a passenger car at the test bench

Preparation for tests of a passenger car at the test bench

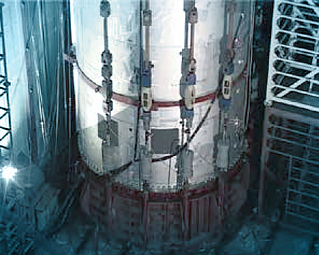

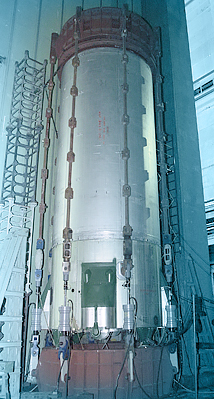

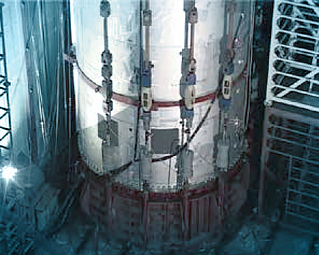

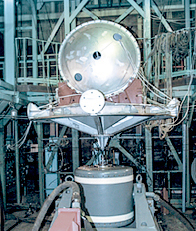

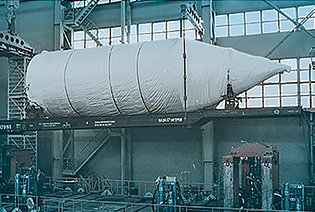

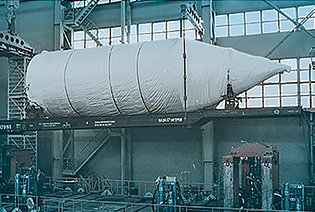

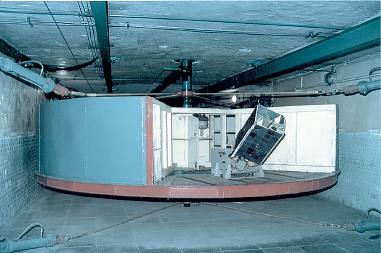

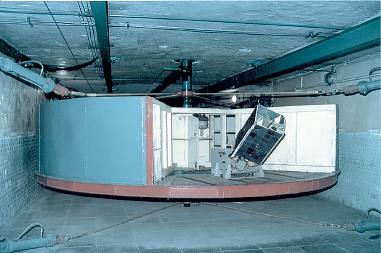

Preparation for tests of payload fairing at the test bench

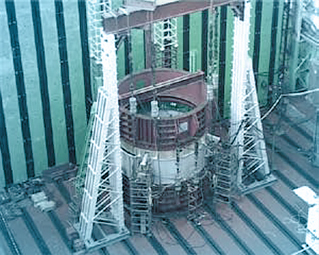

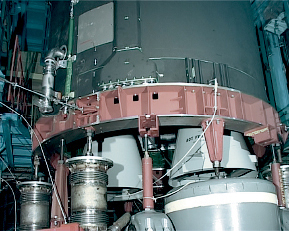

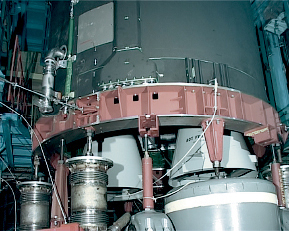

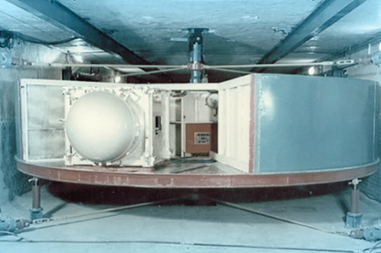

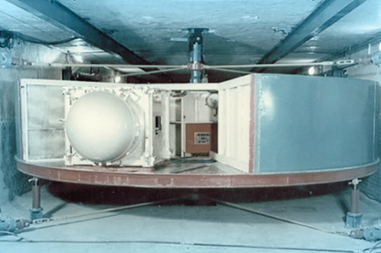

Test bench air dampers

Preparation for tests of a passenger car at the test bench

Preparation for tests of a passenger car at the test bench

Preparation for tests of payload fairing at the test bench

Test bench air dampers

During full-scale tests of large-sized objects for a case of rail, ground, and sea transportation, the data are measured and analyzed by an automated measurement system, a 256-parameter set of small-sized equipment for installation on mobile objects, which is located in a laboratory rail car.

Shock tests are run at different shock test benches providing a shock pulse duration of 0.4 to 15 ms, for a test article weighing up to 50 kg with a maximum size of 300 × 400 × 500 mm.

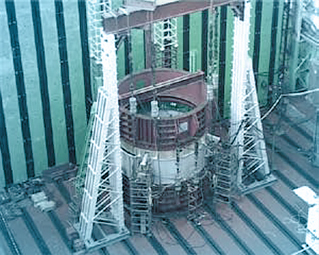

Preparation for seismic-resistance tests of a dу = 200 gate valve for a nuclear power plant at the test bench

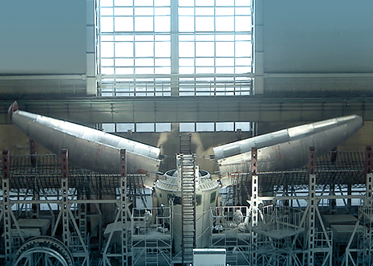

Testing a wind turbine support test structure at a test cell

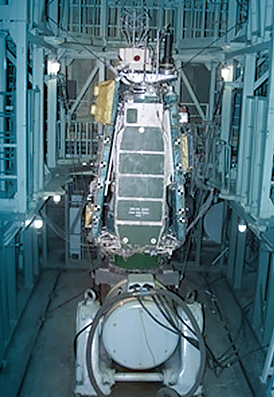

Spacecraft model vibration tests

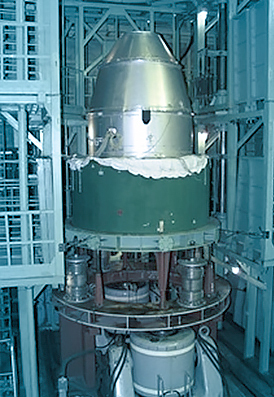

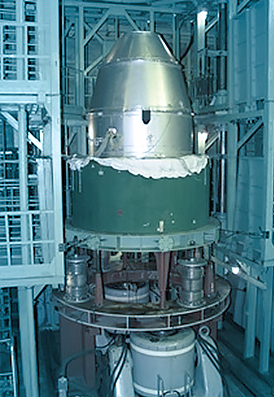

launcher payload module vibration tests

Microsatellite model vibration tests

Microsatellite model vibration tests

launcher payload module vibration tests

Spacecraft model vibration tests

Testing a wind turbine support test structure at a test cell

Preparation for seismic-resistance tests of a dу = 200 gate valve for a nuclear power plant at the test bench

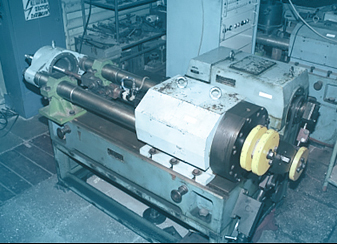

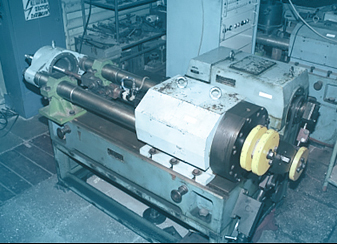

Spacecraft, fuel injection system components, and other articles are tested for linear g-loads at a centrifugal test bench.

| Test article size, m, not more than | 1х1х1 |

| Test article mass, tons, not more than | 1 |

| Linear g-load range, g | 1-20 |

Testing a microsatellite model for linear g‑loads

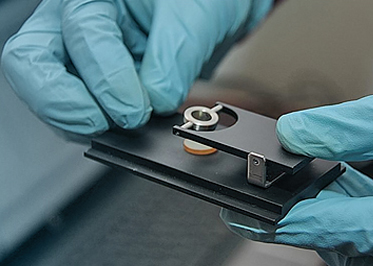

Testing fuel injection system components for linear g‑loads

Testing a microsatellite model for linear g‑loads

Testing fuel injection system components for linear g‑loads

| Dynamic force, kgf, not more than | 500 |

| Steady-state force, kgf, not more than | 800 |

| Total cyclic load, tf, not more than | 100 |

| Frequency, Hz, not more than | 24 |

The tests are run using special-purpose equipment in cells with load-carrying walls, floor and protective/load-carrying convertible ceiling. The cells are equipped with overhead cranes.

| Useful area (length х width х height), m | 25х16х20, 18х11х32 |

| Permissible force per one running meter of the wall or floor, tf, not more than | 50 |

| Permissible bending moment per wall or floor beam, tf, not more than | 300 |

| Overhead crane capacity, tons, not more than | 80 |

https://autocaravanasgayo.com/servicios/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://atharveducation.com/bds.php/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://tunaskaryajakarta.sch.id/