Services

Services

Project description

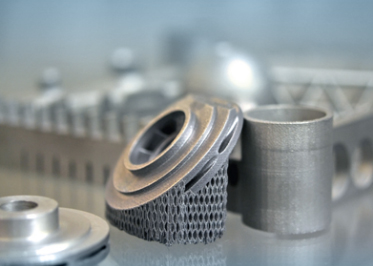

ADDITIVE MANUFACTURING OF METAL PRODUCTS

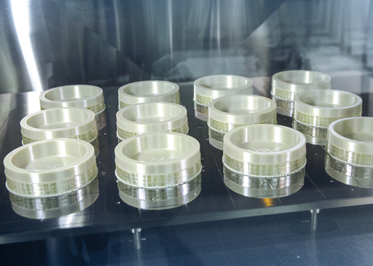

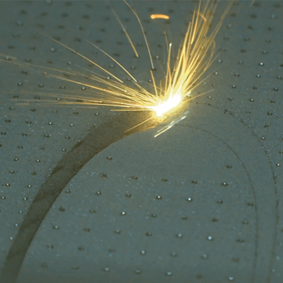

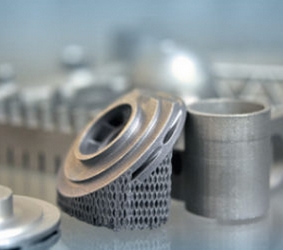

SLM or Selective Laser Melting is an innovative technology for the production of complex products by laser melting of metal powder using mathematical CAD models (metal 3D printing). Yuzhnoye’s SLM shop floor is equipped with a 3D printer to obtain parts with technical performance several times higher than that obtained by a standard casting process. 3D printing allows implementing three-dimensional computer models of parts of any geometry. This technique significantly reduces the time required for the production of prototypes and preproduction parts.

Advantages::

Application field:

| Dimensions of the process chamber, mm | 280×280×350 |

| Manufacturing accuracy | ISO 2768-1 medium accuracy rating |

| Surface roughness | Rz20÷ Rz80 |

| Material | metal powders (316L, Inconel 625, Inconel 718) |

| Dimensions of the process chamber, mm | 280×280×350 |

| Manufacturing accuracy | ISO 2768-1 medium accuracy rating |

| Surface roughness | Rz20÷ Rz80 |

| Material | metal powders (316L, Inconel 625, Inconel 718) |

Related projects

https://autocaravanasgayo.com/servicios/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://atharveducation.com/bds.php/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://tunaskaryajakarta.sch.id/