Services

Services

Project description

Experimental and Commercial Production

Experimental and Commercial Production

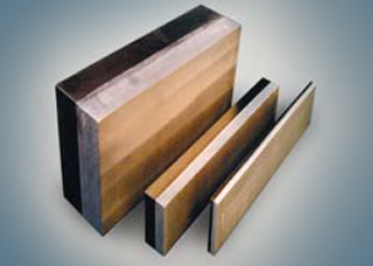

METALS EXPLOSION WELDING

METALS EXPLOSION WELDING

Yuzhnoye SDO proved to be a reliable partner on the global market, building successful cooperation with the world’s leading space companies. YSDO accomplished great number of international contracts with foreign customers and participated in a series of international projects.

With more than 30-year successful experience in the production of bimetallic details, YSDO offers services in metals welding with the explosive energy and guarantees to treat every customer on the case-by-case basis and select the most suitable metal composition and size of material blanks.

Explosion welding is a method of welding based on the application of the explosive energy.

In the process of explosion welding, the weld (moving) part is placed over the fixed part and starts moving in the process of controlled explosion as a result colliding with the fixed part at a great velocity. Connection forms due to the plastic deformation of the contact surfaces.

Explosion welding yields high-quality welded joints out of compatible and non-compatible metals and preserves output physical-mechanical and geometric properties of metal structures around the welded connection.

COMBINATIONS OF LAYERS:

Steel – industrial aluminium – aluminum alloy. Thickness of layers – 40-2-40, 15-2-20, 5-2-5 mm;

Yuzhnoye SDO proved to be a reliable partner on the global market, building successful cooperation with the world’s leading space companies. YSDO accomplished great number of international contracts with foreign customers and participated in a series of international projects.

With more than 30-year successful experience in the production of bimetallic details, YSDO offers services in metals welding with the explosive energy and guarantees to treat every customer on the case-by-case basis and select the most suitable metal composition and size of material blanks.

Explosion welding is a method of welding based on the application of the explosive energy.

In the process of explosion welding, the weld (moving) part is placed over the fixed part and starts moving in the process of controlled explosion as a result colliding with the fixed part at a great velocity. Connection forms due to the plastic deformation of the contact surfaces.

Explosion welding yields high-quality welded joints out of compatible and non-compatible metals and preserves output physical-mechanical and geometric properties of metal structures around the welded connection.

COMBINATIONS OF LAYERS:

Steel – industrial aluminium – aluminum alloy. Thickness of layers – 40-2-40, 15-2-20, 5-2-5 mm;

Copper – industrial aluminium – aluminum alloy.

Thickness of layers – 20-2-20, 5-2-0 mm;

Copper – industrial aluminium – aluminum alloy.

Thickness of layers – 20-2-20, 5-2-0 mm;

Copper – titanium – copper.

Thickness of layers – 5-5-5 mm

Copper – titanium – copper.

Thickness of layers – 5-5-5 mm

Stainless steel – copper – brass.

Thickness of layers – 2-2-2-… mm.

Stainless steel – copper – brass.

Thickness of layers – 2-2-2-… mm.

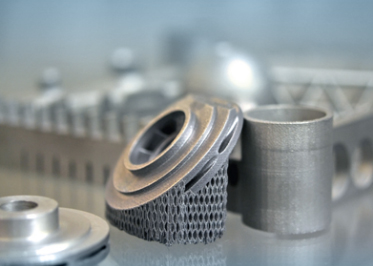

Transition elements of different metal compositions, welded by explosion with subsequent punching and mechanical treatment.

Transition elements

Titanium – niobium – copper – stainless steel.

Thickness of layers – 10-1-1-8.

Transition elements of different metal compositions, welded by explosion with subsequent punching and mechanical treatment.

Transition elements

Titanium – niobium – copper – stainless steel.

Thickness of layers – 10-1-1-8.

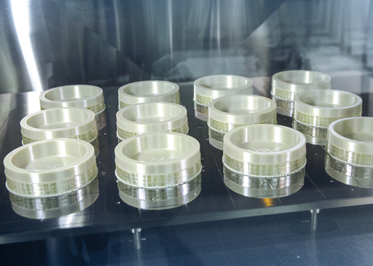

Slide bearings

Slide bearings

Carbon steel-aluminium-tin-base alloy.

Thickness of layers – 10-5 mm.

Carbon steel-aluminium-tin-base alloy.

Thickness of layers – 10-5 mm.

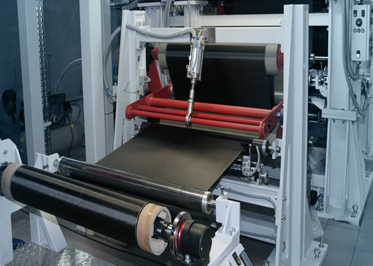

Sputtering targets

Used to obtain thin films (integrated circuits, photographic masks, semiconductors), and inside the installations used to spray the corrosion-resistant coatings. Technically clean metal – copper. Thickness of layers – 10-5 mm.

Sputtering targets

Використовують для отримання тонких плівок (інтегральних схем, фотошаблонів, напівпровідників), а також в установках, що застосовують для напилювання корозійностійких покриттів. Технічно чистий метал – мідь. Товщина шарів – 10-5 мм.

Related projects

https://autocaravanasgayo.com/servicios/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://atharveducation.com/bds.php/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://tunaskaryajakarta.sch.id/