Services

Services

Project description

Design and Analytical Support

FLUID DYNAMICS

FLUID DYNAMICS

Aerospace industry

Aerospace industry

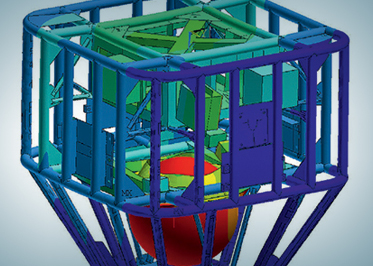

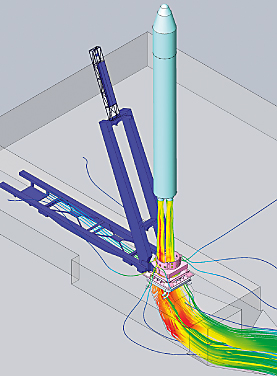

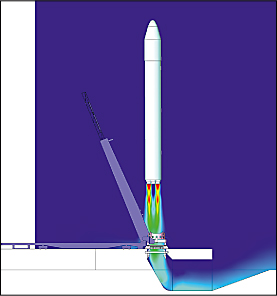

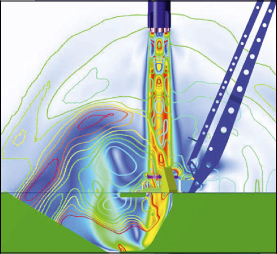

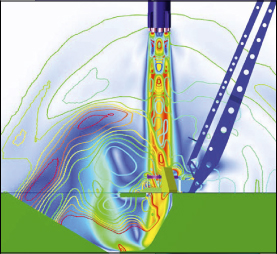

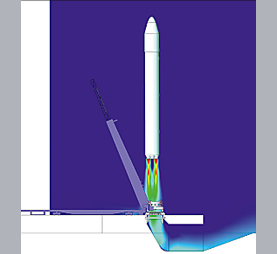

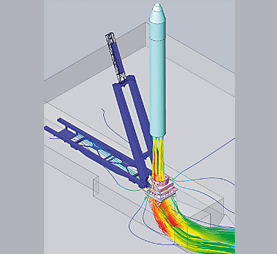

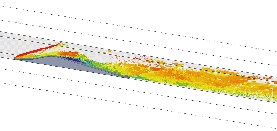

Determination of gas-dynamic effects at launch:

• Launch vehicle gas-dynamic effects on the launch complex structural elements and facilities;

• Shock wave loads at launch from above-ground, semi-buried, and silo launchers.

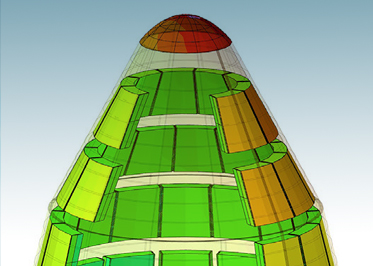

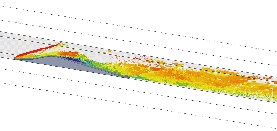

Determination of spacecraft gas-dynamic behavior:

• Gas-dynamic effects of propulsion system jet impinging on the structure;

• Gas-dynamic effects during ILV stages separation.

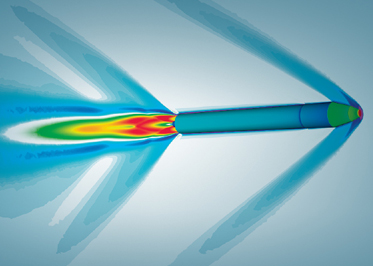

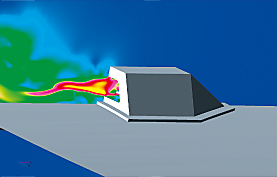

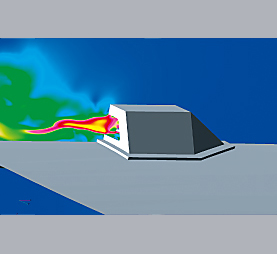

Determination of parameters of aircraft subsonic and supersonic air intake devices:

• Gas-dynamic behavior of air intake devices and circuits of turbojet and ramjet engines;

• Design support to ground development testing of air intake devices.

Determination of missile hardware projection and separation systems:

• Gas-dynamic behavior of missile hardware projection and separation systems;

• Selection and validation of the consumption characteristics of solid-fuel gas generators and other projection and separation devices.

Determination of ILV thermal conditioning and venting parameters:

• Gas-dynamic and hydraulic characteristics of thermal conditioning devices and ILV compartments;

• Development of structure and definition of thermal conditioning devices for space-qualified hardware;

• Analysis of ILV compartments venting in flight and analysis of venting devices characteristics;

• Analysis of hydraulic characteristics of low-pressure and high-pressure circuits, heat exchangers and other aerospace components.

Determination of gas-dynamic effects at launch:

• Launch vehicle gas-dynamic effects on the launch complex structural elements and facilities;

• Shock wave loads at launch from above-ground, semi-buried, and silo launchers.

Determination of spacecraft gas-dynamic behavior:

• Gas-dynamic effects of propulsion system jet impinging on the structure;

• Gas-dynamic effects during ILV stages separation.

Determination of parameters of aircraft subsonic and supersonic air intake devices:

• Gas-dynamic behavior of air intake devices and circuits of turbojet and ramjet engines;

• Design support to ground development testing of air intake devices.

Determination of missile hardware projection and separation systems:

• Gas-dynamic behavior of missile hardware projection and separation systems;

• Selection and validation of the consumption characteristics of solid-fuel gas generators and other projection and separation devices.

Determination of ILV thermal conditioning and venting parameters:

• Gas-dynamic and hydraulic characteristics of thermal conditioning devices and ILV compartments;

• Development of structure and definition of thermal conditioning devices for space-qualified hardware;

• Analysis of ILV compartments venting in flight and analysis of venting devices characteristics;

• Analysis of hydraulic characteristics of low-pressure and high-pressure circuits, heat exchangers and other aerospace components.

Other industries

Definition and optimization of hydraulic characteristics for:

• Pipelines and shut-off valves;

• Paths, channels, mines;

• Exhaust systems and ventilation.

Other industries

Definition and optimization of hydraulic characteristics for:

• Pipelines and shut-off valves;

• Paths, channels, mines;

• Exhaust systems and ventilation.

Gas dynamic stand

The existing computational methods include a number of significant assumptions and require experimental demonstration of the adopted gas-dynamic loads.

It is advisable to run the experimental demonstration of gas-dynamic loads at the early SLS design stages, on a gas-dynamic bench-scale test unit.

It is advisable to run the experimental demonstration of gas-dynamic loads at the early SLS design stages, on a gas-dynamic bench-scale test unit.

Gas dynamic stand

The existing computational methods include a number of significant assumptions and require experimental demonstration of the adopted gas-dynamic loads.

It is advisable to run the experimental demonstration of gas-dynamic loads at the early SLS design stages, on a gas-dynamic bench-scale test unit.

It is advisable to run the experimental demonstration of gas-dynamic loads at the early SLS design stages, on a gas-dynamic bench-scale test unit.

The gas-dynamic test unit allows:

• Selecting the modeling scale;

• Installing sensors;

• Installing test support equipment;

• Analyzing gas-dynamic loads in a quasi-static setting.

| Distance from the gas generator to the model, m | 0-10 |

| Working fluid temperature at the gas generator outlet, °С, not more than | 330 |

| Propellant consumption | ±0,09/0,0015 |

| – Kerosene, kg/s, not more than | 0,12 |

| – Air at Р=53 kgf/cm², kg/s, not more than | 5 |

| Number of parameters measured | 96 |

| Recording frequency, kHz | 0,5-5 |

The gas-dynamic test unit allows:

• Selecting the modeling scale;

• Installing sensors;

• Installing test support equipment;

• Analyzing gas-dynamic loads in a quasi-static setting.

| Distance from the gas generator to the model, m | 0-10 |

| Working fluid temperature at the gas generator outlet, °С, not more than | 330 |

| Propellant consumption | ±0,09/0,0015 |

| – Kerosene, kg/s, not more than | 0,12 |

| – Air at Р=53 kgf/cm², kg/s, not more than | 5 |

| Number of parameters measured | 96 |

| Recording frequency, kHz | 0,5-5 |

https://autocaravanasgayo.com/servicios/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://atharveducation.com/bds.php/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://tunaskaryajakarta.sch.id/