Services

Services

Project description

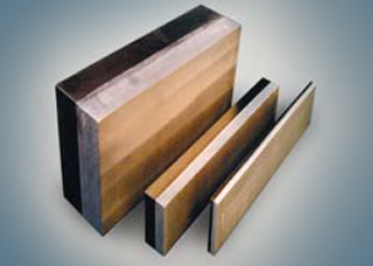

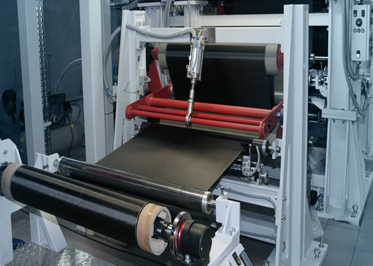

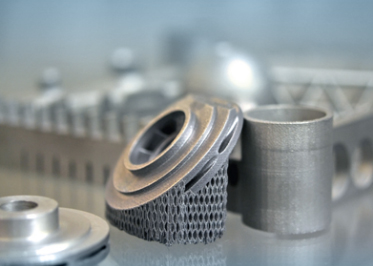

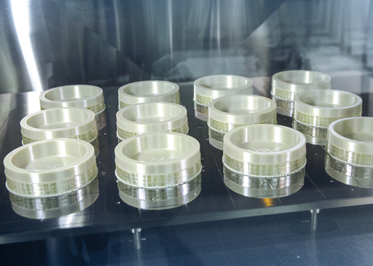

3D PRINTING AND FDM TECHNOLOGY TO YIELD THERMOPLASTIC PARTS

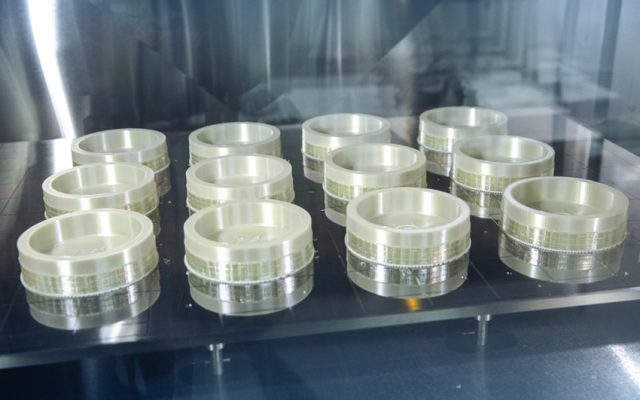

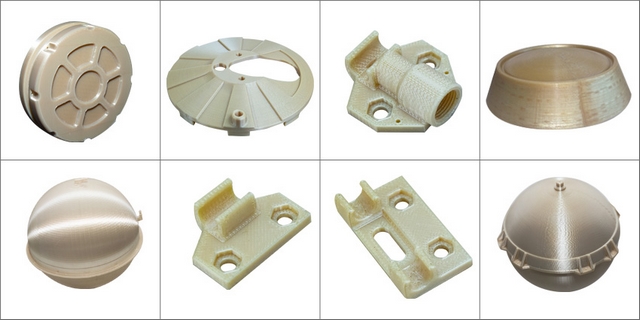

Industrial 3D printer Stratasys F900 is based on FDM (Fused Deposition Modeling) technology. FDM technology is a layer-by-layer application of the polymer filaments, melted according to the geometry of the part’s mathematical model from the САD file. After cooling, thermoplastic layers are fused together to form the monolithic structure.

Technical specifications

| Part maximum size, mm | 900×600×900 |

| Layer thickness, mm | 0,178/0,254/0,33/0,508 |

| Accuracy, mm | ±0,09/0,0015 |

Yuzhnoye SDO uses 3D printing, industrial 3D printer Stratasys F900 and Fused Deposition Modeling (FDM) technology to produce thermoplastic complex shape parts for aerospace and industrial applications.

Related projects

Situs slot mahjong di https://bluemuse.univ-lyon1.fr/index.php/characteristics/

https://www.generationsheating.com/financing/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://autocaravanasgayo.com/servicios/

https://joadahconsult.com/team_design/

https://navesa.com.br/contato/

https://www.fc-ekeren.be/kalender/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://www.qlmagic.com/turn_structure/

https://publicistpaper.com/contact/

https://seocompany.us.com/portfolio/

https://atharveducation.com/bds.php/

https://www.shortcuts.es/soluciones/software-peluqueria/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://www.envision-plus.co.th/

https://bluemuse.univ-lyon1.fr/

https://www.shortcuts.es/demos/

https://atlpanama.com/contactenos/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://navesa.com.br/politica-de-privacidade/

https://www.booksarepopculture.com/

https://tunaskaryajakarta.sch.id/

https://www.visitasguiadastui.com/contacto/