Services

Services

Project description

HOT FIRE TESTS

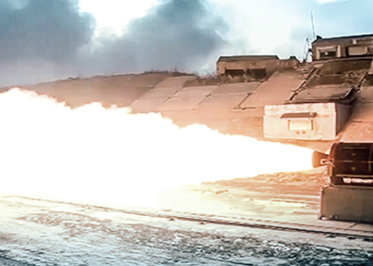

Test firings are the functional tests of items with fire path. Functionality of the test items is checked in the bench test conditions, simulating the flight conditions and testing initiation and shutdown modes, as well as measuring main characteristics.

Yuzhnoye SDO together with subcontracting organizations tests liquid-propulsion engines (mono- and bipropellant), solid-propellant engines (large-size and small-size), liquid jet propulsion systems, rocket engine combustion chambers, gas generators, burners etc.

Hot fire tests are functional tests of products with a fire path. The tests measure performance capabilities of the engine/motor in testbed environment, with flight modes simulated, engine/motor startup and cutoff verified, and general performances measured. The test objects include mono- and bipropellant liquid-propellant rocket engines, solid-propellant rocket motors, liquid-propellant jet systems, rocket engine combustion chambers, preburners, nozzles, etc.

of liquid-propellant

rocket engines

and associated,

assemblies and units

in a pressure chamber

The following liquid-propellant rocket engine (LRE) tests can be performed:

The tests are conducted using unsymmetrical dimethylhydrazine and nitrogen tetroxide as propellants, with a technological capability of testing with monomethylhydrazine.

Test firings are the functional tests of items with fire path. Functionality of the test items is checked in the bench test conditions, simulating the flight conditions and testing initiation and shutdown modes, as well as measuring main characteristics.

Yuzhnoye SDO together with subcontracting organizations tests liquid-propulsion engines (mono- and bipropellant), solid-propellant engines (large-size and small-size), liquid jet propulsion systems, rocket engine combustion chambers, gas generators, burners etc.

of liquid-propellant

rocket engines

and associated,

assemblies and units

in a pressure chamber

The following liquid-propellant rocket engine (LRE) tests can be performed:

The tests are conducted using unsymmetrical dimethylhydrazine and nitrogen tetroxide as propellants, with a technological capability of testing with monomethylhydrazine.

The test facility supports:

| LRE | LPS | LTPS | |

| Thrust, tons, up to | 1 | 0,1 | 0,01 |

| Propellant supply pressure, kgf/cm2, up to | 200 | 20 | 40 |

| Propellant thermal conditioning, °С | 0…+50 | +5…+35 | +0…+50 |

| Hardware thermal conditioning, °С |

-70…+35 | -180…+35 | +5…+35 |

| Gas saturation (degassing) to specified values | to specified values | ||

| Full-scale environment simulation at nozzle exit, kgf/cm2 | ~0,004…0,008 | ~0,014…0,2 | ~0,004…0,13 |

| LRE | LPS | LTPS | |

| Thrust, tons, up to | 1 | 0,1 | 0,01 |

| Propellant supply pressure, kgf/cm2, up to | 200 | 20………………….. | 40………………….. |

| Propellant thermal conditioning, °С | 0…+50 | +5…+35 | +0…+50 |

| Hardware thermal conditioning, °С |

-70…+35 | -180…+35 | +5…+35 |

| Gas saturation (degassing) to specified values | to specified values |

||

| Full-scale environment simulation at nozzle exit, kgf/cm2 | ~0,004…0,008 | ~0,014…0,2 | ~0,004…0,13 |

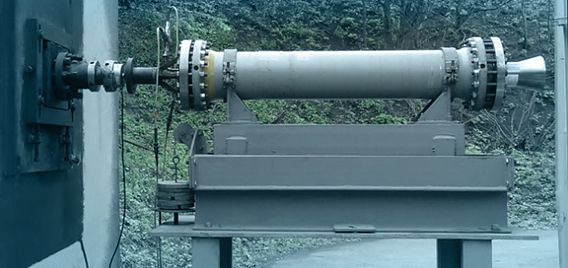

The vacuum chamber with a gas-dynamic pipe and a gas-ejector plant, allowing gases to flow continuously from the nozzle, supports LRE tests in quasi-operational environments.

| Test article size, m, not more than | Ø3,1х1,6 |

| External pressure at nozzle exit, kgf/cm2 | 0,00015-0,2 |

| Number of measured parameters | 538 |

rocket motor

hot fire tests

The vacuum chamber with a gas-dynamic pipe and a gas-ejector plant, allowing gases to flow continuously from the nozzle, supports LRE tests in quasi-operational environments.

| Test article size, m, not more than | Ø3,1х1,6 |

| External pressure at nozzle exit, kgf/cm2 | 0,00015-0,2 |

| Number of measured parameters | 538 |

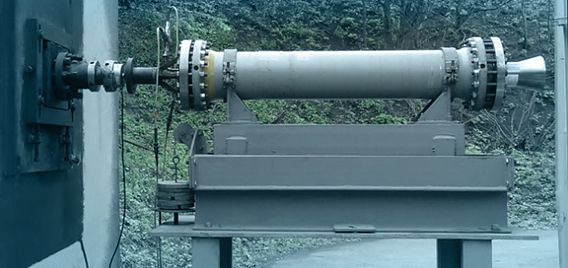

rocket motor

hot fire tests

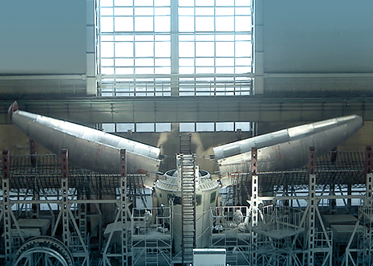

The hot fire test bench for large SRM features measurement and recording equipment to measure combustion chamber pressure and pulsations, motor thrust, vibration, temperature, SRM structure displacement and deformation during the test. The test bench includes high-speed filming and thermal imaging equipment.

The test bench for small SRM features measurement and recording equipment to measure combustion chamber pressure, motor thrust, temperature, SRM structure displacement and deformation during the test. The test benches feature photography and video filming equipment.

The test benches available support vibration and shock tests, and the heat and cold chambers support accelerated environmental tests and alternating thermal conditioning upstream HFT.

SPECIFICATIONS ACCOMMODATED BY SRM TEST BENCHES

| Specification | Large SRM | Small SRM |

| Test bench measured thrust, tnf | 0 … 150 | 0 … 15 |

| Test SRM mass, kg | 500 … 40000 | 0.1 … 600 |

| Test SRM diameter, mm | 500 … 2400 | 50 … 500 |

| Thermal conditioning range, °С |

– 40 … +50 | – 40 … +50 |

| Maintenance personnel protection | The maintenance personnel works remotely from an armored bunker | The maintenance personnel works remotely from a armored cell |

The test benches available support vibration and shock tests, and the heat and cold chambers support accelerated environmental tests and alternating thermal conditioning upstream HFT.

SPECIFICATIONS ACCOMMODATED BY SRM TEST BENCHES

| Specification | Large SRM…………………..………… | Small SRM…………………..………… |

| Test bench measured thrust, tnf | 0 … 1500 | 0 … 15 |

| Test SRM mass, kg | від 500 до 40000 | 0.1 … 600 |

| Test SRM diameter, mm | 500 … 2400 | 50 … 500 |

| Thermal conditioning range, °С |

– 40 … +50 | – 40 … +50 |

| Maintenance personnel protection | The maintenance personnel works remotely from an armored bunker | The maintenance personnel works remotely from a armored cell |

Situs slot mahjong di https://bluemuse.univ-lyon1.fr/index.php/characteristics/

https://www.generationsheating.com/financing/

https://exin.se/flytt-och-transport/

https://exin.se/produkt/skap-kinnarps/

https://autocaravanasgayo.com/servicios/

https://joadahconsult.com/team_design/

https://navesa.com.br/contato/

https://www.fc-ekeren.be/kalender/

https://www.internacionaldvdspain.com/articles/decoracion/

https://exin.se/flytt-och-transport/

https://www.qlmagic.com/turn_structure/

https://publicistpaper.com/contact/

https://seocompany.us.com/portfolio/

https://atharveducation.com/bds.php/

https://www.shortcuts.es/soluciones/software-peluqueria/

https://odin.rvbar.ru/poster/vorovayki/

https://newnoardicwave.com/privacy-policy/

https://www.envision-plus.co.th/

https://bluemuse.univ-lyon1.fr/

https://www.shortcuts.es/demos/

https://atlpanama.com/contactenos/

https://einkaufsgemeinschaft.agritec.at/aktionen/

https://alejandrodavidovich.com/

https://mycreativitymypower.eu/

https://navesa.com.br/politica-de-privacidade/

https://www.booksarepopculture.com/

https://tunaskaryajakarta.sch.id/

https://www.visitasguiadastui.com/contacto/